Enabling Automation in Motion and Control

At NSK, we enable you to pioneer new technology and increase your competitive advantage in your markets. Whether it’s Medical, Lab Automation, Semiconductor, Machine Tool, 3D Printing or Factory Automation, we innovate to save you valuable internal resources and time. We exist to improve your cost efficiency and increase your speed to market. We partner with you; the one-stop-shop for all your automation needs.

3D Printing

Robotics

Autonomous Vehicles

Injection Molding

Integrated Systems

Laboratory Automation

Medical Equipment

Medical Imaging

Robotic Surgery

Factory Automation

Expertise You Can Count On

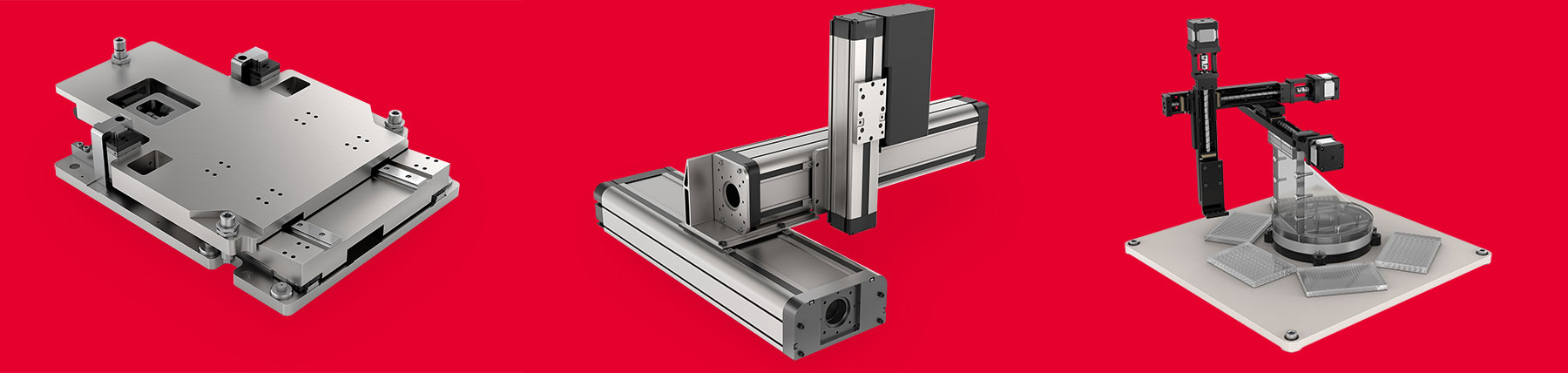

Integrated Mechatronic Systems

Accelerate product development, simplify procurement and speed up production using NSK’s renowned mechatronics expertise to design a pre-configured, pre-built and fully tested motion system. Integrated systems utilize NSK’s core products and technology to ensure the high quality synonymous to the NSK brand, as well as locally-based Application Engineers to work closely with customers from design and testing, to installation and maintenance.

Americas Technical Center (ATC)

The NSK Americas Technical Center has been conducting considerable research, testing and analysis using a variety of analytical systems, and technological innovation in the field of mechatronics and bearings, including:

- Visual analysis of failure and fracture using digital photography and measurement

- Metrology using dimensional, coordinate and form measurements

- Chemical analysis using scanning electron microscope, compound analysis and particle counting

- Metallurgical evaluation of the microstructure and macrostructure, as well as hardness measurements, case depth measurements, metallographic preparation, fractography and steel cleanliness evaluation

- Noise and vibration assessments using internally developed software and equipment, in addition to advanced analysis tools such as Fast Fourier Transform (FFT), enveloping, and bearing fault frequencies. The labs also include 2 semi-anechoic chambers as well as noise, vibration, and harshness (NVH) test stands