Factory Automation

Accelerating automation and smart technology for Industry 4.0.

Products

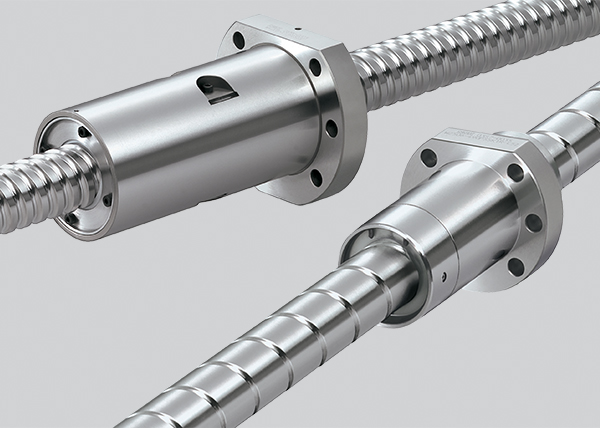

Ball Screw

- Highest accuracy, durability, rigidity and smoothest motion

- Range include miniature ball screws to ultra-large sizes, with C0 to C7 accuracy grades

- Fully customizable ball screws manufactured locally in Franklin, IN

- Employs revolutionary tribology (friction control) technology

Linear Guide

- Achieve smooth, quiet linear motion for various accuracy levels and load ratings

- Sliders/ carriages and profile rails are stocked

- Linear slide rail can be cut to desired length for quick turnaround

- Comes in size 5 to 65 mm

- We have Linear Guides for standard quick delivery, miniature, wide rail, high load, etc.

- V1 High-performance seals and K1 Lubrication units ensure long-term, maintenance-free operation

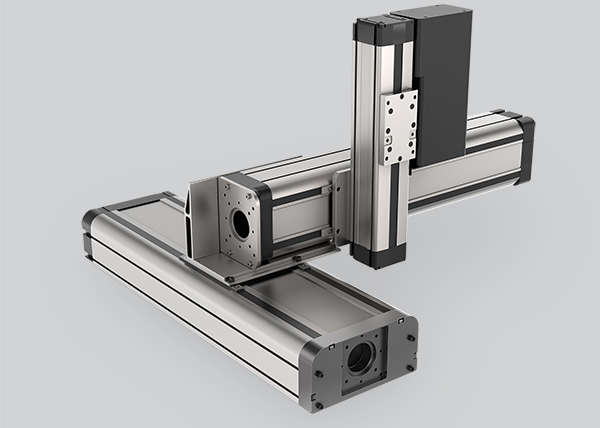

Linear Actuator

- Compact, lightweight, high precision linear positioners with C5 or C7 accuracy

- Speeds up to 2500mm/ second and acceleration up to 5G

- Single-axis linear positioner that integrates NSK’s precision ground ball screw, linear guide and support bearings

- Options include the popular MCM series, high rigidity MCH series, and the ultra-high load, roller-based TCH series

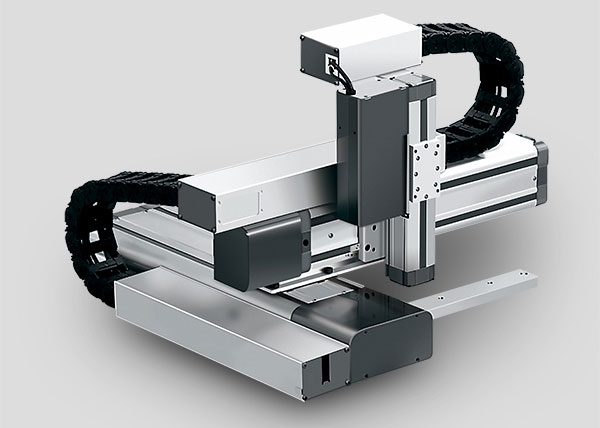

Robot Module

- Linear actuators made for simple and easy integration into single or multi-axis positioning table

- Housed in a machine-extruded aluminum

- Designed to accept a variety of motor interfaces using standard kits

- Mounting plates and combining brackets available to easily configure an X-Y-Z linear stage

- K1 Lubrication comes standard to ensure maintenance-free operation up to 5 years or 10,000 km of travel

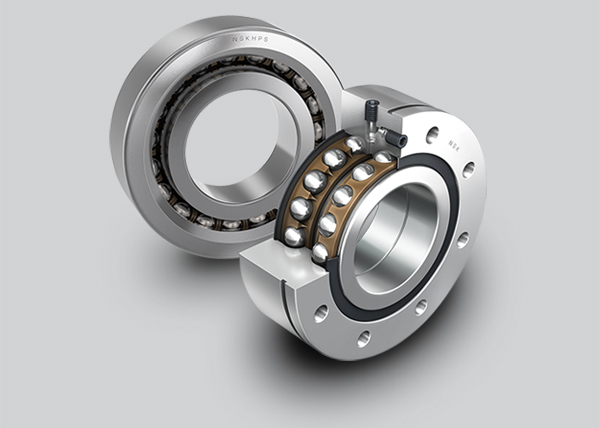

Ball and Roller Bearings

- The foundation of the NSK brand, manufactured for over 100 years

- Extensive design and manufacturing capabilities for specialty applications or extreme sizes

- Exceptional reliability and performance

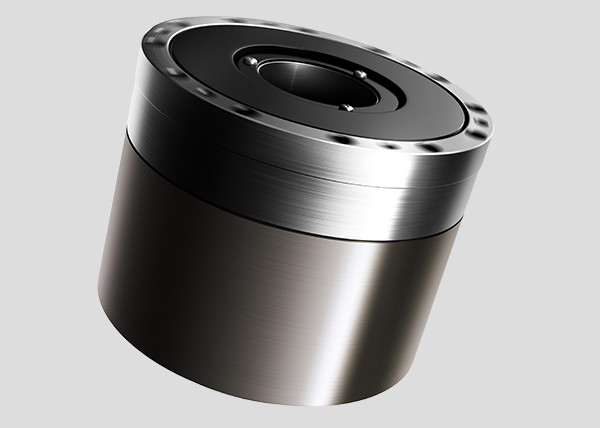

Direct Drive Motors

- Resolution of over 2.6 million counts/ revolution

- Exceptional repeatability of ±2 arc-sec

- NSK Megatorque Motor/ Rotary Indexer delivers remarkable performance

- Ideal for positioning applications requiring high accuracy and speed in a very compact size

- PN/Z series is a pancake style motor that provides the lowest profile and highest rigidity for heavy loads

- PS series delivers high rotational speeds for medium/ light loads

Integrated Mechatronic Systems

Accelerate product development, simplify procurement and speed up production using NSK’s renowned mechatronics expertise to design a pre-configured, pre-built and fully tested motion system. Integrated systems utilize NSK’s core products and technology to ensure the high quality synonymous to the NSK brand, as well as locally-based Application Engineers to work closely with customers from design and testing, to installation and maintenance.

The NSK Difference

NSK is leading the charge to enable our customers

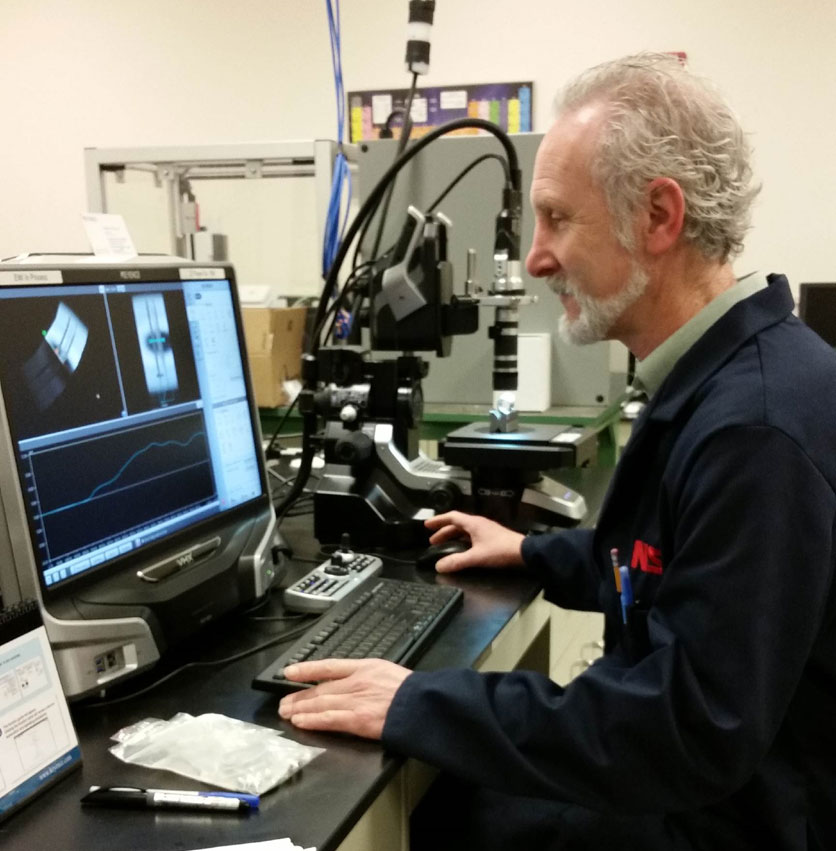

Using condition monitoring systems such as the NSK BD2 and Acous Navi™ technology, we help customers diagnose linear bearings based on bearing pulse vibration data to determine

In addition to NSK’s proprietary technology, NSK’s Application Engineers and Americas Technical Center (ATC) also execute comprehensive root cause analyses of premature bearing, linear guide or ball screw failures in industrial automation applications. We recommend countermeasures or new product specifications that can significantly reduce wear or contamination, boost performance, and improve life.

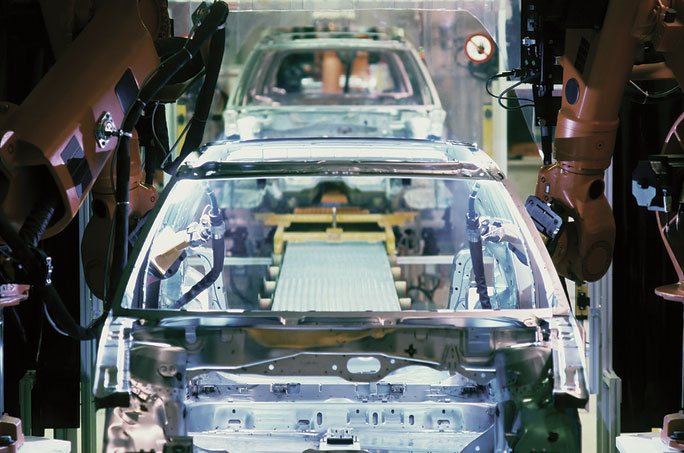

Case Study: Nut Runner System for Transmission Case Assembly

An automotive OEM required an automated nut runner system moving in X, Y or Z axis, to tighten nuts individually within a predefined travel parameter set.

Pain Point

The OEM posed a tough challenge for a transmission case assembly process: zero failure and zero downtime.

Three-axis Robot Module Nut Runner System

Solution

NSK proposed a three-axis Robot module designed with high stiffness to accommodate the heavy load of the customer’s nut runner process. Not only did the NSK Robot Module’s very precise, controlled motion reduce the deformation and oil leak from the transmission case, the efficient connection points for XYZ stages also ensured simple installation and minimal set-up time.

Equipped with K1 lubrication units for maintenance-free operation up to 5 years or 10,000 km travel, the NSK Robot Module reduced downtime and increased OEE for the nut runner line.

Since the customer relied on NSK to deliver a fully assembled system, design validation for loaded life, rigidity