Linear Guides

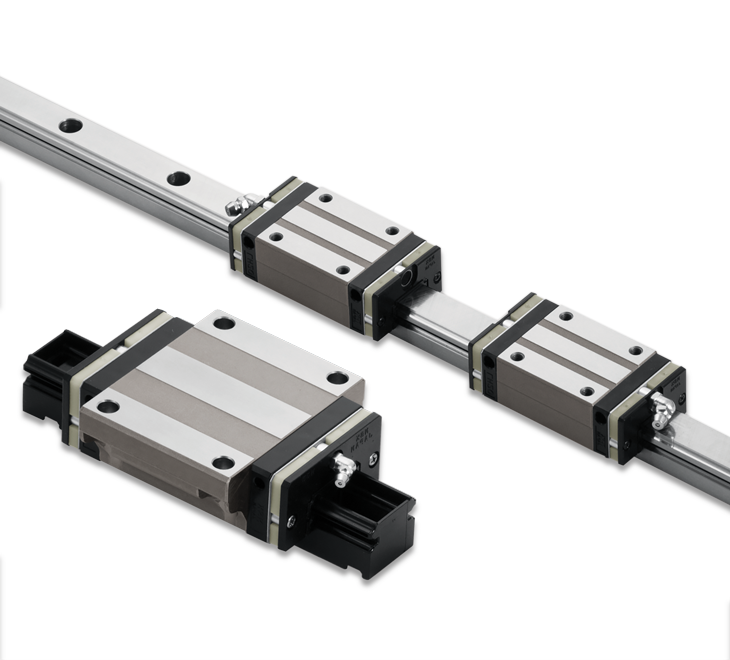

From multiple-ton industrial dies to millimetrically-precise medical imagers, NSK linear guides deliver accurate, smooth, repeatable linear motion optimized for every application. From the miniature PU Series to the maximum-load NH/NS line, NSK linear guides can be combined with innovations like V1 high-performance seals and K1 lubrication units for long-lasting performance in contaminant-prone environments.

- Smooth, quiet, reliable linear motion for virtually every load rating

- Broad selection stocked for quick shipping and deployment

- Standard and custom Linear Rail designs available with a range of coatings and lubricants

Linear Guides

|

|

|

||

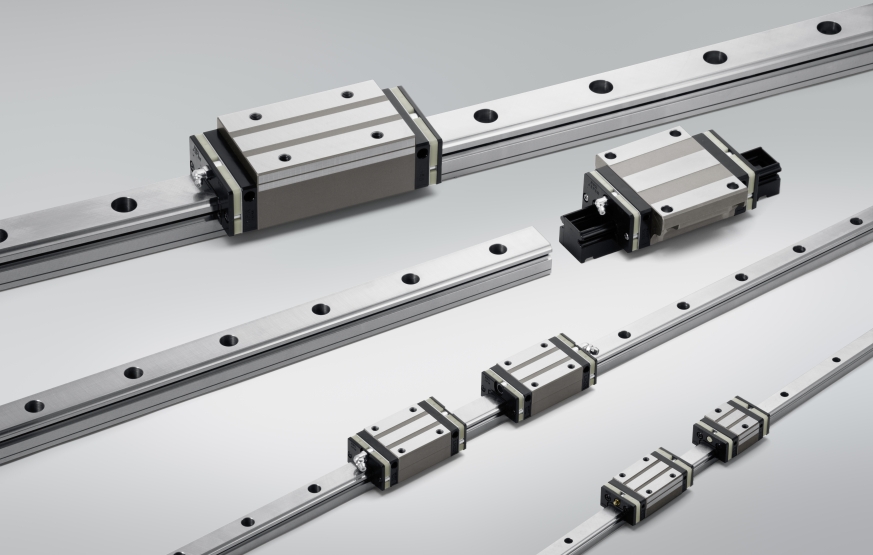

| LINEAR GUIDE TYPE | Miniature Linear Guides |

Ball Linear Guides |

Roller Linear Guides |

|

Miniature Linear Guides typically used in Semiconductor and Life Science applications |

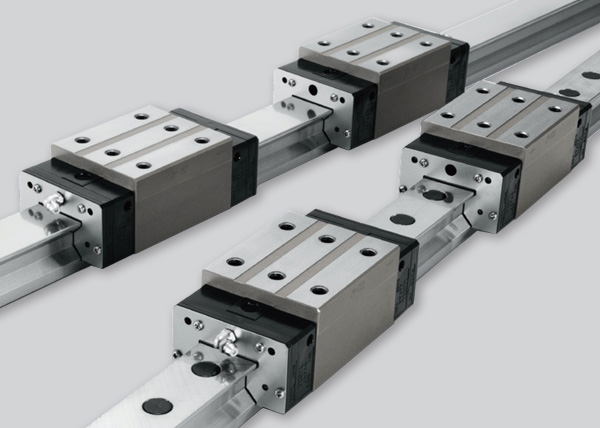

Ball Linear Guides typically used in automation and general industry applications |

Roller Linear Guides typically used in machine tool and heavy industry applications |

||

Model Type |

PU and PE (wide rail) |

NH and NS (low profile) |

DH and DS (long life) |

RA and RB (low profile) |

Bearing Type |

Ball |

Ball |

Ball |

Roller |

Bearing Circuits |

2 |

4 |

4 |

4 |

Load Capability |

Moderate |

High |

High |

Extreme |

Speed (m/s) |

Moderate |

High |

High |

Moderate |

Acceleration (g) |

High |

High |

High |

Moderate |

Interchangeable Components |

Yes |

Yes |

Yes |

Yes |

Accessories |

K1 Lubrication Unit, Rail Caps |

K1 Lubrication Unit, HP Seals for Contamination, Special Materials and Coating Available |

K1 Lubrication Unit, HP Seals for Contamination, Special Materials and Coating Available |

K1 Lubrication Unit, HP Seals, Special Materials and Coating Available, Rail Covers or Hole Caps |

Base Material |

Stainless Steel (SUS440) |

Steel (SCM420H) |

Steel (SCM420H) with TF (Tough) Technology |

Steel (SCM420H) |

Delivery* |

From stock |

From stock |

From stock |

From stock |

*Subject to sale

Ready To Ship 3-5 Days

NSK’s Quick Ship Program ensures quick access to Linear Guides and Ball Screws in most sizes within 3-5 days.

Offering rapid fulfillment across the US and internationally. Need modifications? Customize NSK Quick Ship parts to fit your exact specifications. Switch to NSK today for fast, dependable service that keeps your operations seamless.

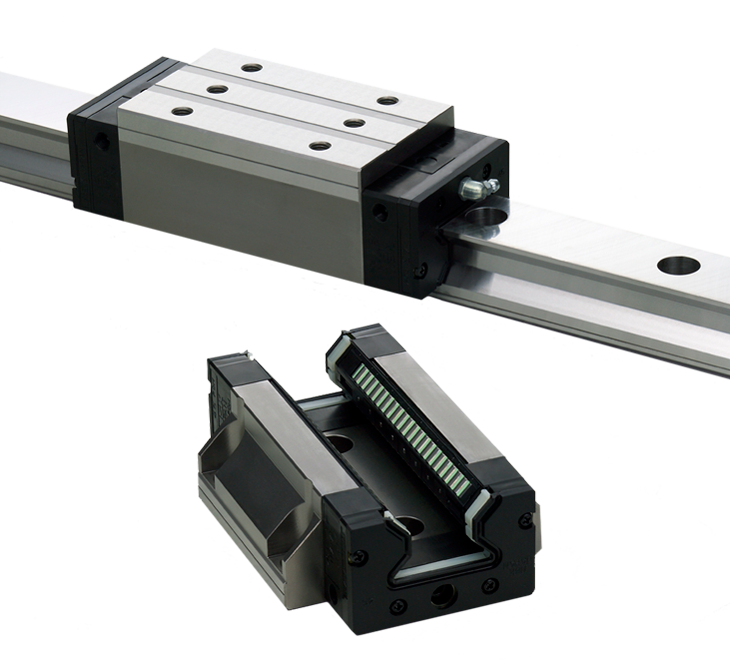

Linear Guide Accessories

Optional accessories to complement your NSK Linear Guide

V1 Sealing System

Highly dust proof V1 seal helps extend service life under contaminated environments

- High dust-resistance (multi-lip structure seal)

- Long operating life

- Available in multiple sizes

K1™ Lubrication Unit

- Long-term maintenance free

- Reduction in maintenance cost

- Extended life in severe operating conditions

- Reduced environmental impact

Case Study: Band Cutter Linear Guides in a Dough Machine

Technical Challenge

A bakery was experiencing continual failures of their band cutter linear guides, which were not holding up to the required performance standards. The linear guides required replacement every 3 weeks, causing excessive maintenance, downtime and lost production.

NSK NH/NS Series Linear Guides

NSK Solution

NSK proposed high-speed stainless steel linear guides, with food-grade K1 lubrication units. Although the new linear guides were double the cost of the original Armoloy-coated units, the service life improved ten-fold, increasing output and decreasing downtime, with a total cost savings of $219,924.

Integrated Mechatronic Systems Solutions

Enabling automation in motion and control

Our local integration and manufacturing teams will collaborate closely with you through all aspects of design, provide intensive project management and extend comprehensive technical support.

Design and Development

- system design proposal with

CAD model - component failure analysis and benchmarking

- material technologies

- applications simulation

Project Management

- design review – as many as 5

- quote – non-recurring engineering, prototype, full production

- prototype demonstration

- test report

- lead time/production schedule

- individual system test before shipping

After Sales Service

- on-site support for system installation

- training

- bill of materials for replacement parts